Unique Requirements and Challenges

High-volume production with mixed discrete, process, and repetitive manufacturing is hard to optimize in standard SAP PP.

Configure SAP PP/PP-PI and advanced planning tools. Implement SAP APO/IBP or custom enhancements for sequencing, capacity leveling, and simulation.

Unique Requirements and Challenges

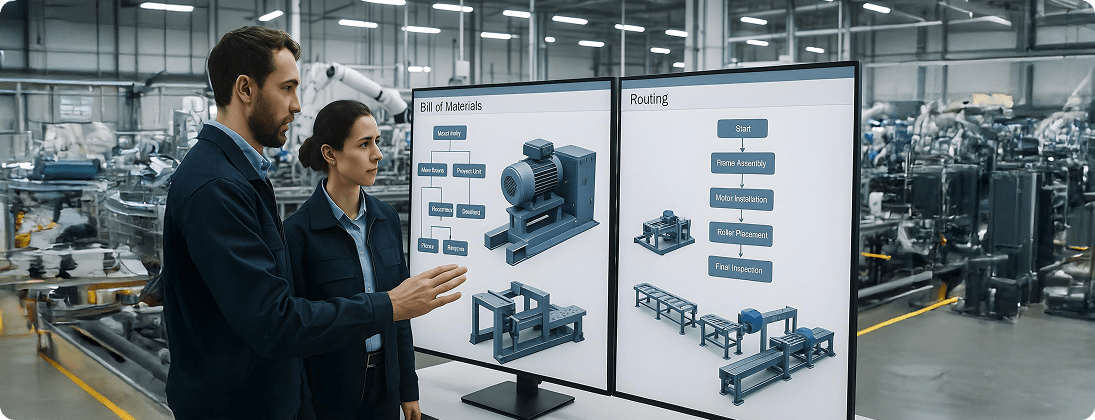

Multiple BOM alternatives, variants, and engineering changes often create inconsistencies.

Streamline BOM and routing management with change control. Automate engineering change management (ECM) and integrate with PLM systems.

Unique Requirements and Challenges

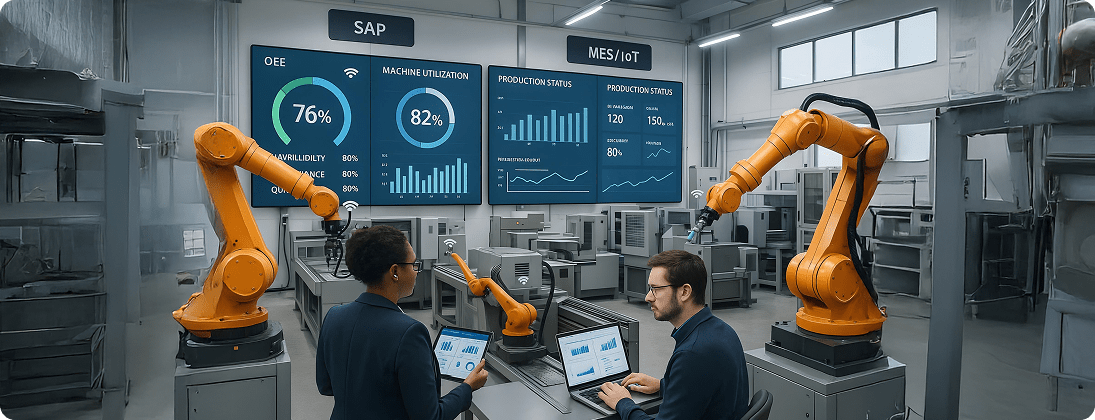

Disconnected shop floor systems limit real-time visibility into production and quality.

Integrate SAP ERP with MES (SAP MII, SAP DMC) and IoT platforms. Provide dashboards for OEE (Overall Equipment Effectiveness) and machine data capture.

Unique Requirements and Challenges

Product recalls, non-conformance, and regulatory compliance (ISO, IATF, FDA, etc.) are high-risk.

Implement SAP QM across procurement, production, and sales. Automate inspection lots, defect tracking, and Certificates of Analysis (COA).

Unique Requirements and Challenges

Excess stock, stockouts, and poor visibility across plants/distribution centers reduce margins.

Configure SAP EWM/WM with advanced inventory strategies (FIFO, FEFO, batch, HU management). Enable real-time tracking with barcode/RFID.

Unique Requirements and Challenges

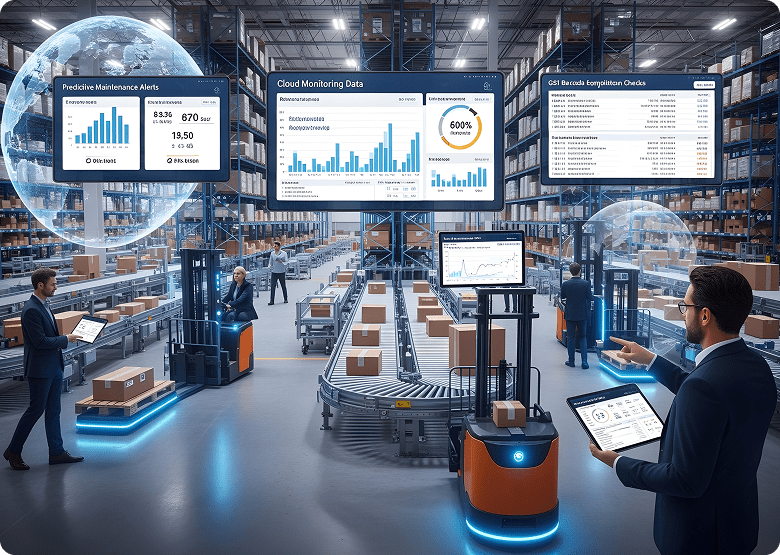

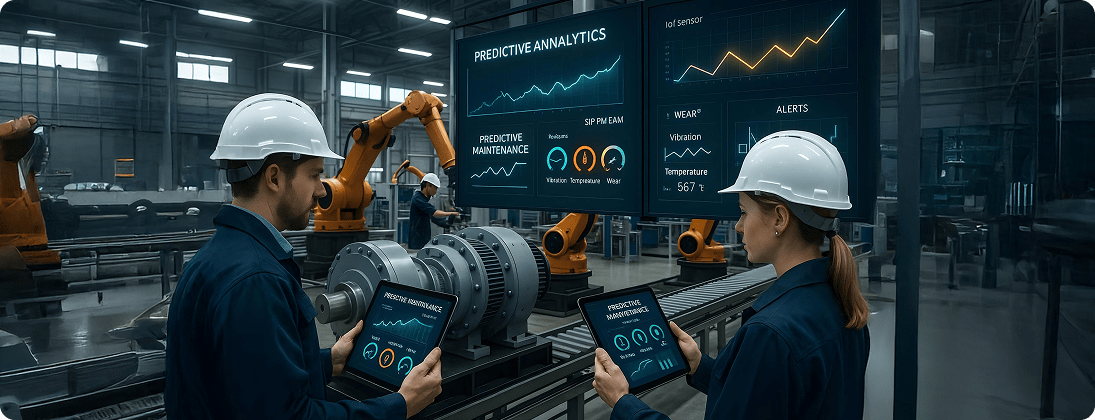

Downtime in equipment-heavy industries impacts production and costs.

Optimize SAP PM/EAM with predictive maintenance. Integrate IoT/SCADA for proactive asset health monitoring.

Unique Requirements and Challenges

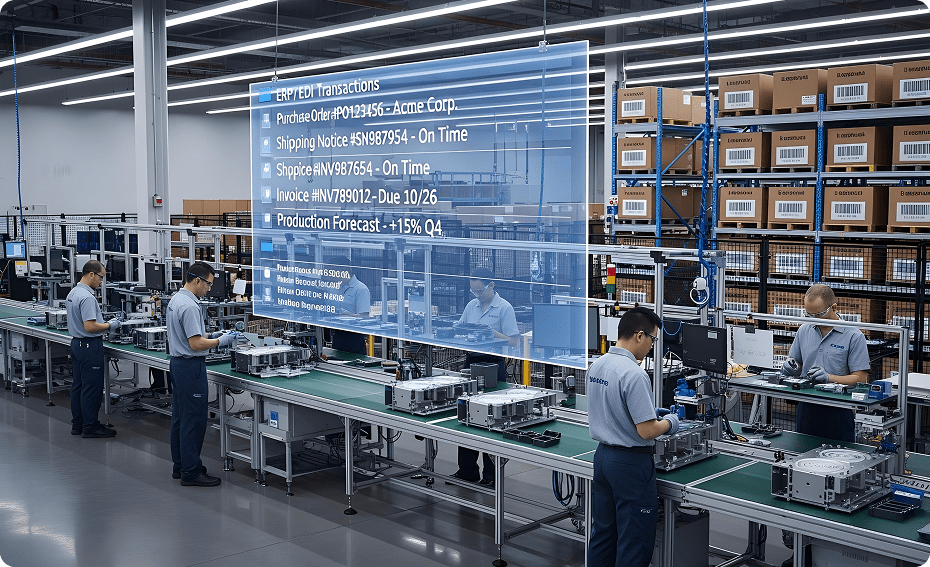

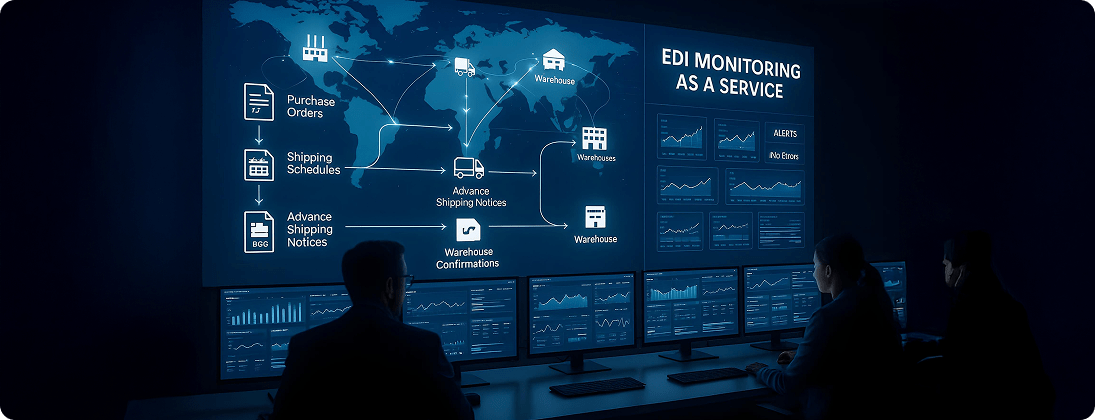

Manufacturers must comply with OEM/customer EDI standards; poor ASN or labeling can lead to chargebacks.

Provide GETR’s proven EDI expertise across 830, 862, 856, 940/945, etc. Deliver “EDI Monitoring as a Service” to eliminate errors and penalties.

Unique Requirements and Challenges

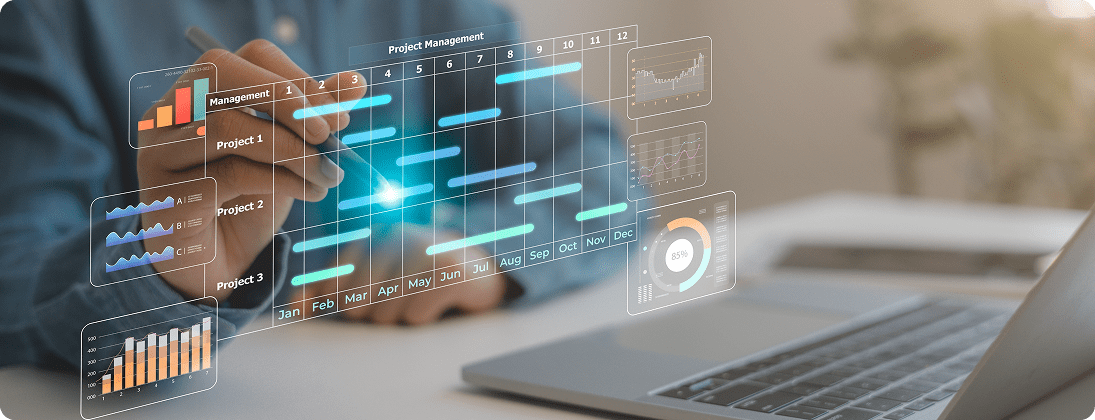

Multiple plants, geographies, and ERP versions create inconsistencies in process execution.

Standardize global templates for SAP rollouts. Provide harmonized master data and process governance.

Unique Requirements and Challenges

Inaccurate product costing impacts pricing and margins.

Configure SAP CO-PC for standard and actual costing. Build dashboards for margin analysis, scrap variances, and cost recovery.

Unique Requirements and Challenges

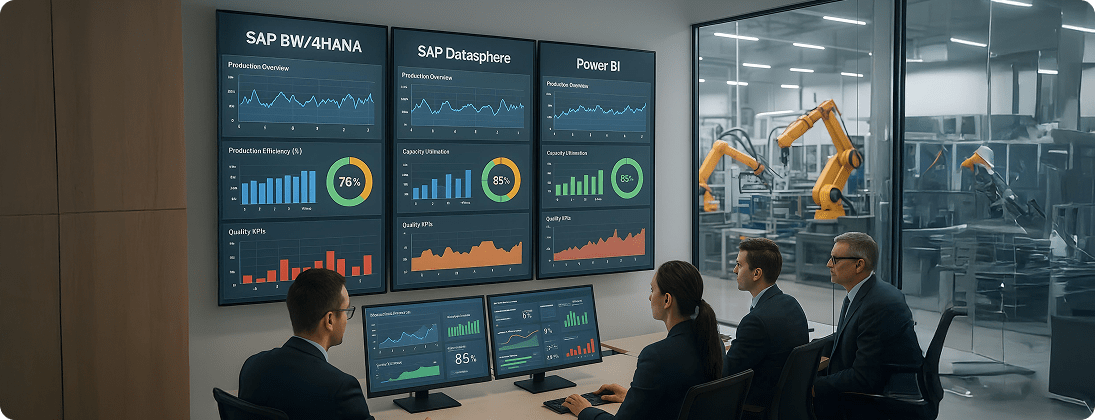

Executives lack timely insights into production KPIs, yields, and supply chain bottlenecks.

Develop SAP BW/4HANA, Datasphere, or Power BI dashboards. Deliver real-time analytics for production efficiency, capacity, and quality.