Unique Requirements and Challenges

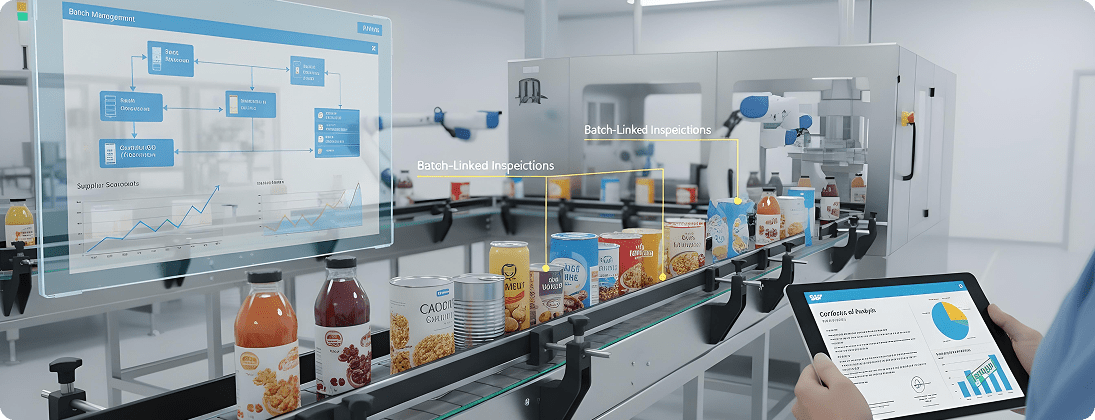

Compliance requires strict batch traceability. Many companies struggle with incomplete or disconnected batch processes in SAP.

Configure SAP batch management with integrated quality processes. Enable full traceability across procurement, production, and sales.

Unique Requirements and Challenges

Inaccurate tracking leads to write-offs, compliance risks, or lost sales.

Implement shelf-life expiration date (SLED) control and FEFO picking in WM/EWM to minimize waste and ensure compliance.

Unique Requirements and Challenges

Flexible recipes, substitutions, and potency variations are hard to manage in SAP PP-PI.

Optimize BOMs, recipes, and production versions for scalable manufacturing. Enable real-time formula adjustments.

Unique Requirements and Challenges

Nutrition, allergens, and origin labeling often exceed SAP’s out-of-the-box capabilities.

Build SAP-integrated custom labels with nutritional and allergen data. Automate printing via WM/EWM and 3rd-party tools (NiceLabel, Bartender).

Unique Requirements and Challenges

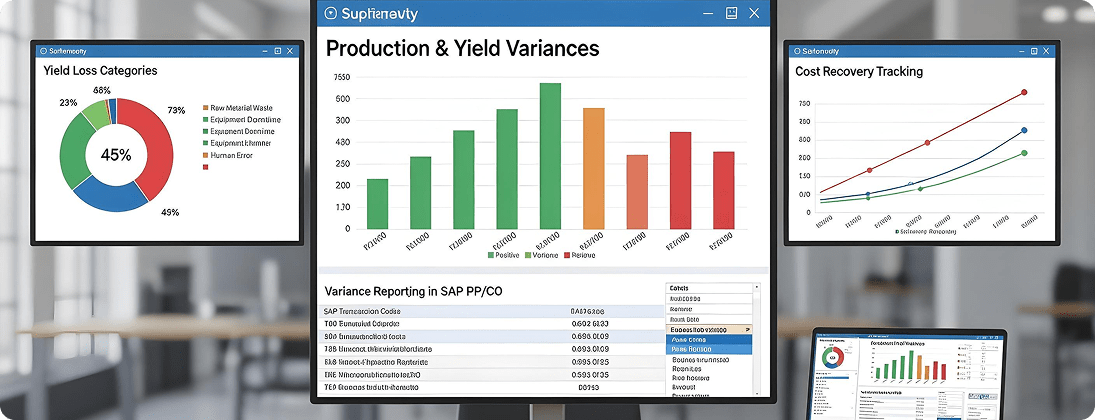

Spoilage, evaporation, and inefficiencies drive hidden costs.

Configure variance reporting in SAP PP/CO. Build dashboards to track yield losses and cost recovery.

Unique Requirements and Challenges

Inline inspections and COAs are not automated. Vendor quality is hard to monitor.

Implement SAP QM with batch-linked inspections. Automate Certificates of Analysis and supplier scorecards.

Unique Requirements and Challenges

Temperature-sensitive logistics and FEFO/FIFO picking are poorly supported in many plants.

Configure EWM for temperature zones and FEFO. Integrate barcode/RFID scanning for real-time cold chain monitoring.

Unique Requirements and Challenges

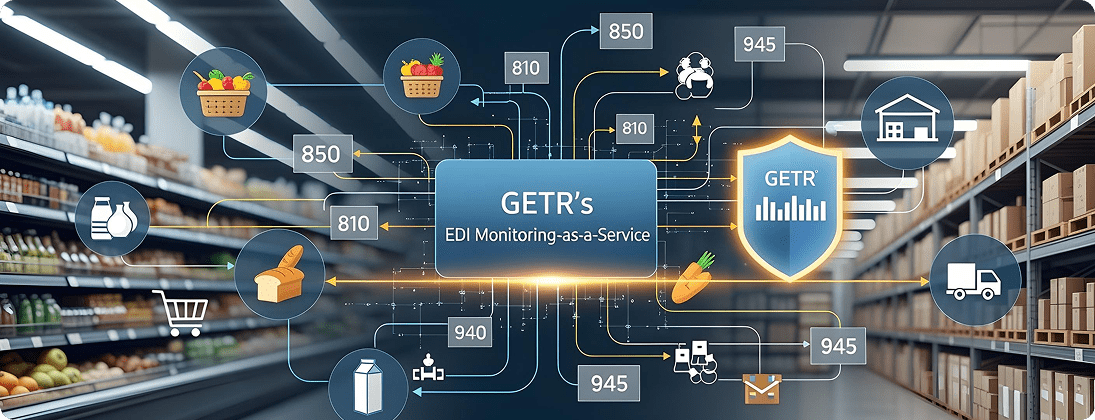

Chargebacks due to failed ASNs, incorrect labels, or delayed EDI.

GETR’s EDI Monitoring-as-a-Service prevents errors. Expertise across 850, 856, 810, 940, 945, etc. ensures compliance with major retailers/distributors.

Unique Requirements and Challenges

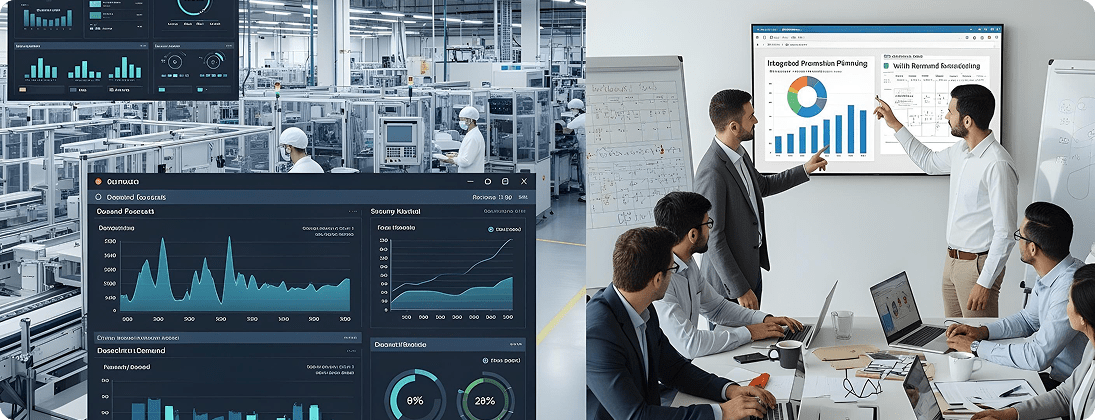

Seasonal spikes and promotions cause frequent stockouts or overstocks.

Enhance MRP and integrate promotion planning. Provide on-demand fractional consultants for seasonal scaling.

Unique Requirements and Challenges

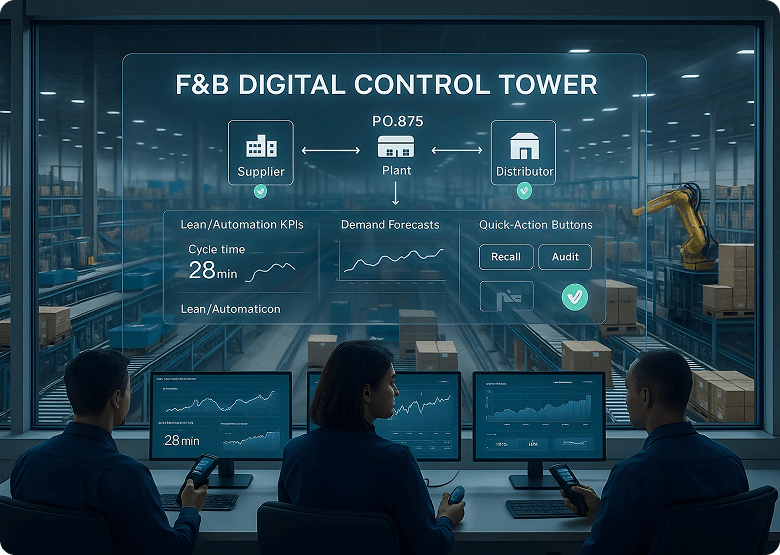

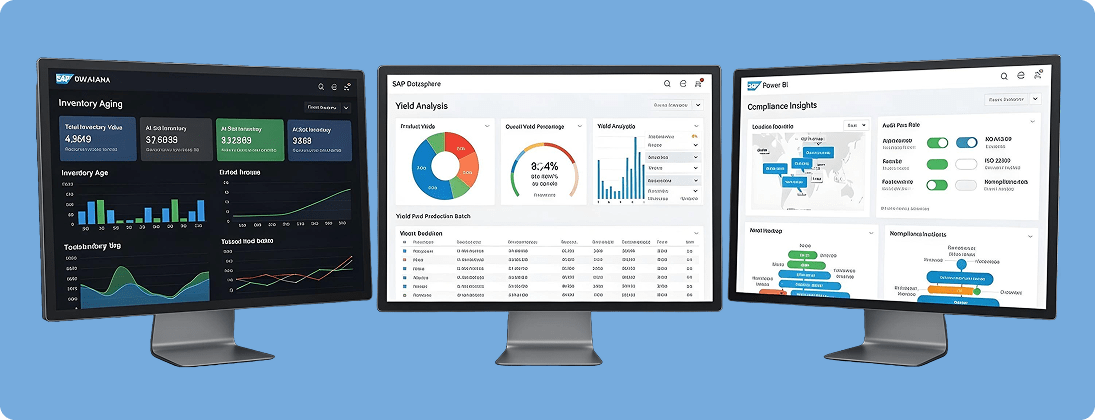

Lack of real-time dashboards limits decision-making at both plant and executive level.

Deliver SAP BW/4HANA, Datasphere, or Power BI dashboards for inventory aging, yields, and compliance insights.

Unique Requirements and Challenges

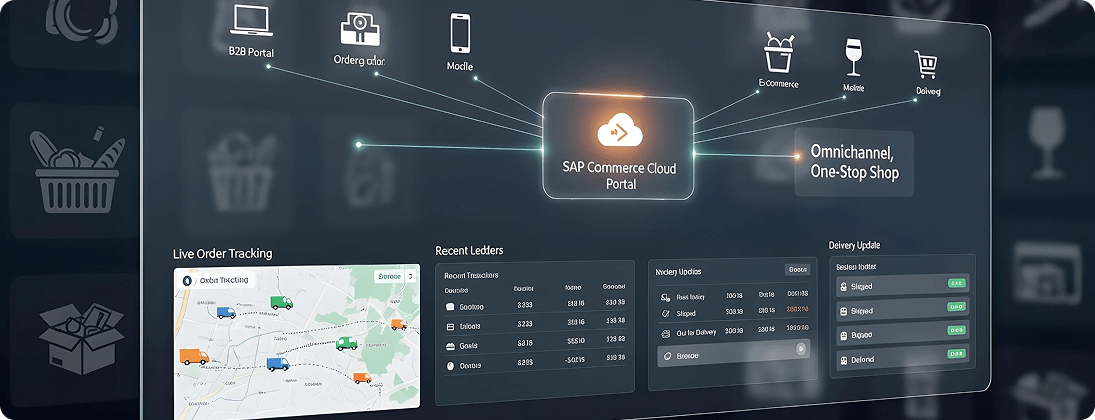

Multiple ordering channels resulting in time-consuming processes, potential errors and lack of uniform process.

Digital self-service portal using SAP Commerce Cloud which ceates an omnichannel (one-stop shop) experience for all the clients (retailers, wholesalers, supermarkets, and distributors) by providing a real-time insights into orders, invoices, and delivery information to them.

Unique Requirements and Challenges

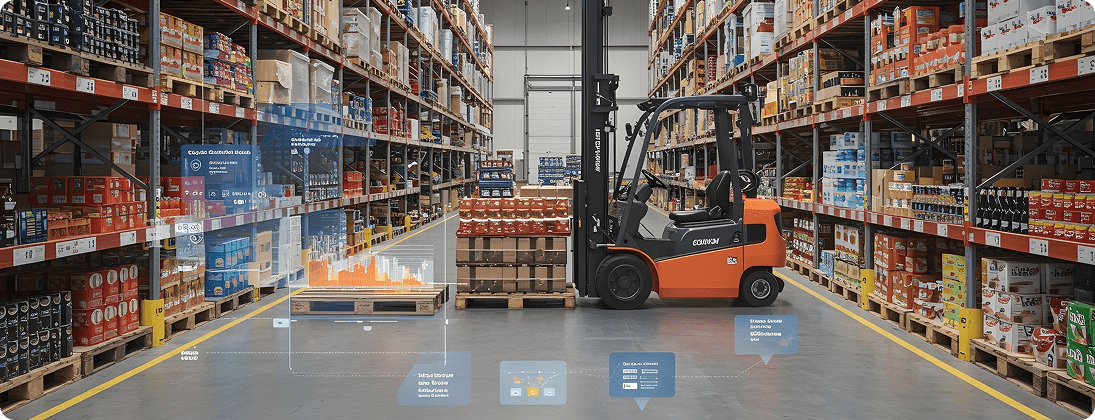

Too much working capital stuck in inventory

Inprovement in inventory turns, reduced inventory, increased operational efficiency & service levels using SAP DDMRP and EWM.

Unique Requirements and Challenges

Consumers expect the brands/producers to use eco-friendly practices, which typically include sustainable packaging, reduce the food waste, sourcing ingredients responsibly. Additionally, there are requirements to keep the carbon footprint lower and adhering to ESG compliance.

SAP Sustainability Control Tower helps F&B companies meet eco-friendly goals by tracking carbon footprint, monitoring sustainable packaging, ensuring responsible sourcing, reducing food waste, and simplifying ESG compliance reporting.

Global delivery centers (U.S., Mexico, India) with 24×7 coverage.